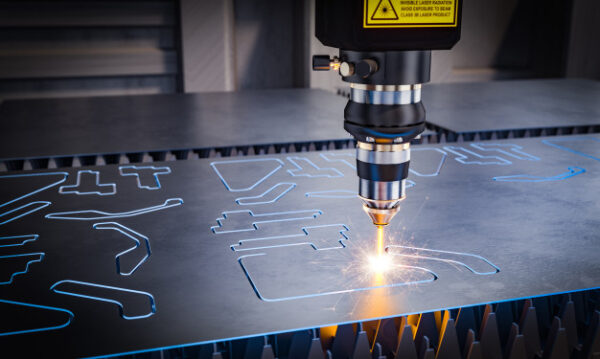

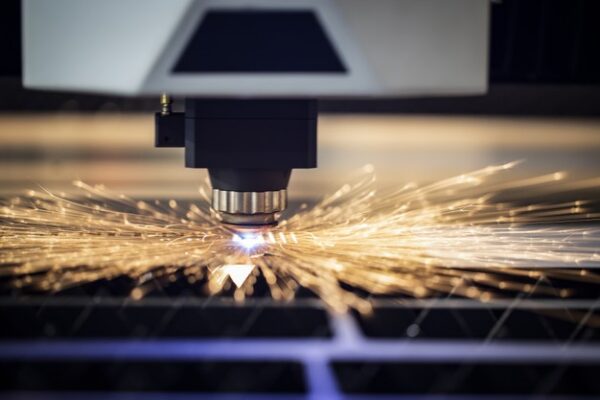

Laser cutting is, possibly, the most frequently applied manufacturing process across hundreds of industries. In fact, it has been utilized in the automotive, medicinal, microelectronics, and aerospace sectors, which is something that makes it quite clear that this innovative technology has a wide range of advantages and benefits.

However, if you aren’t familiar with these machines, you might be wondering – why is this technology indispensable in most industries? Fortunately for all individuals that are asking themselves the same question, the article below will shed some light on the entire topic. So, without further ado, let’s take a closer look:

The Industries That Use These Devices

You should know that the slicing techniques function in various ways, which means that these extremely precise devices offer an improved level of precision and quality. This is why a lot of industries utilize them, especially since they could cut almost any substance out there. The industries that these mechanisms are most frequently used in are:

1. Aerospace

If there is one sector that must be precise, it’s the aerospace sector. This is why they rely on laser devices since they offer the diversity and precision needed for manufacturing mechanical components. Even the tiniest pieces need to be formed and drilled correctly and without mistakes, and the only devices that’ll meet these requirements are lasers.

2. Automotive

Similar to the aforementioned sector, this one also cannot function without the tiniest and most intricate parts. Only lasers could produce clear cuts and smooth finishes, however, they’re used for other things too, like separating cloth for airbags since they’ll melt the rims of the cloth, meaning that there won’t be any excess textile left.

3. Electronics

As tech improves, the electronics industry requires to meet the demand of making their goods smaller, which means that traditional techniques cannot be applied anymore. Instead, they utilize extremely precise devices to work on the most intricate and delicate elements such as circuit boards.

4. Medical

This is one of the areas that produced different mechanisms and parts that are incredibly tiny, however, lives really rely on the quality of those goods. The production of medicinal gadgets is the most common application of these devices, and they could also be utilized for making hospital equipment such as bone reamers or vascular clips.

So, What Could They Cut?

Now that you have learned the industries that these devices are most frequently used in, you should also learn what these machines could cut, especially since it’ll make it easier for you to understand why many industries utilize them. So, the elements that you could cut by using these gadgets are:

- Metal – this is the most popular use of these devices. In fact, it could be used for slicing a lot of different metals including steel, aluminum, nickel, as well as brass. No matter what the density of a particular metal is, the device will be able of making precise cuts and you’ll frequently see that these devices are used for structural and part frames. There are various machines on the market such as an enclosed desktop mini laser engraving machine, hence, you should read more about these models.

- Silicon – this substance is quite important across various industries – such as solar and microelectronics – and since it’s one of the materials that we utilize every day, it cannot be denied, these precision gadgets are extremely important for these substances. After all, the components can be precisely cut, meaning that the products manufactured from silicon are now more adaptable since they can be smaller. This is also something that helps with innovations across multiple sectors.

- Ceramics – since this element has different features such as thermic conductivity and electrical insulation, it plays a crucial role in all sectors and it also has a wide range of diverse applications and practices. Additionally, besides slicing ceramics, they could also be easily utilized for inscribing this element, which means that people can now manufacture components or products with complex designs.

- Fabrics + Cardboard – besides all the aforementioned materials, manufacturing plants could also use these machines for slicing fabrics and cardboard. This means that there are various processes and techniques utilized in order to create containers or packaging, as well as boxes or bags. Besides this, it won’t leave any excess materials on the fabrics or cardboard, mostly because it’ll melt the rims instead of severing them.

- Non-Metals – by now, you have probably realized that these devices could be used for cutting a wide range of materials, however, you should know that there is also one more material category that it can be utilized in – non-metals. This means that companies could use it for working on other materials including polymers, glass, rubber, plastics, styrofoam, and carbon composites, meaning that it’s quite beneficial. You will need setup blocks for woodworking. These blocks can help ensure that larger pieces of wood are held in place while they are being cut or manipulated. Setup blocks also help to reduce vibrations and improve accuracy when cutting. Many experienced woodworkers prefer wooden setup blocks as they provide additional stability and cushioning for the material being worked on. These blocks can be easily customized by drilling a hole for a clamp or jigging the surface for a specific use.

Are There Some Benefits to Using These Devices?

There are various benefits that you could gain by utilizing these devices. Besides allowing you to work on different substances and materials, you’ll also be able to gain the following benefits:

- It’ll Allow You to Be Flexible

When you utilize these machines, you won’t need to use any additional equipment and/or tools for making the cuts. In fact, the same settings are suitable for cutting different designs and shapes, no matter what the thickness is. Additionally, with it, you won’t have problems with making complex cuts.

- Accurate And Precise

Another benefit is that you can ensure that the cuts are all accurate and price. And when compared to come traditional methods, you’ll be able to get an accuracy of + or – 0.1mm, which means that you won’t need any after-treatment for the components you’re working on.

- It’s Fast

When compared to some traditional techniques, laser cutting will be faster, especially if there are intricate cuts that need to be made. However, don’t worry, although these machines operate quickly, they’ll still be extremely accurate, meaning that you won’t have to worry about the quality of the product.

Conclusion

Laser cutting technology is utilized in almost every single industry that you can find on the market. After all, it allows companies to work on different materials, it’s flexible and extremely precise, and more importantly, it’s fast, meaning that you’ll be able to make the products you need faster.

So, now that you’re aware of the industries that use these machines, as well as the benefits you could gain, you might not want to waste any more of your time. Instead, open up your browser, and start looking for a laser cutter that will help you manufacture the product you need.